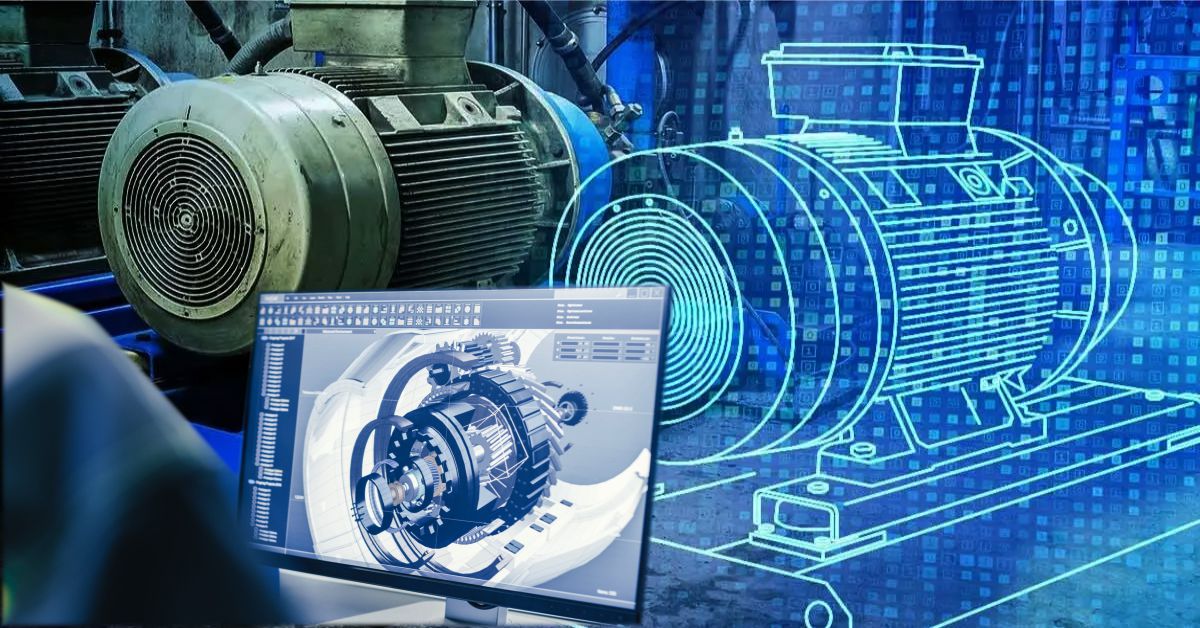

Some platforms are being generated to provide accurate data while others are related to analysis. Whether we talk about inspecting the data or providing us with a pristine format of the information, there is an active component being designed to formulate reports. While talking about effective solutions being created for us in order to provide assistance, the digital twin plays a great role. It is the solution that acts as a dynamic copy of a process, system, physical asset, or even virtual environment.

What is Digital Twin?

Being the virtual model that is designed to precisely contemplate and reflect a physical object. The compelling format of the digital twin is to study the object, and while consisting of the process outfitting it with several sensors affiliated with vital domains of different functionalities. These sensors are being developed to produce data about various aspects related to the physical object and its performance. The performance could be anything related to the objects for instance if we talk about a simple wind turbine, it includes the aspects like temperature, energy output, along with weather conditions, and many more.

Types of Digital Twins

After knowing the concept of digital twin or how digital twin works, let us now go through their various categories. Depending on a different level of product enhancement, there are several effective types of digital twins. It could be added that these aspects of digital twin technology are contrasting with one another in the area of applications. It is also possible to consist of different categories of digital twins existing in a process or system at the same time.

The different types of digital twins are discussed below:.

- Part Twins or Component Twins:

Being referred to as the basic unit of the digital twin, component twins are the smallest specimen of formulating components. It is the simplest example of the digital twin. While on the other hand, part twins could be described as roughly being the same thing, but it involves components of a bit less essentiality.

- Asset Twins:

An Asset is formed with an effective process that involves two or more components working together. It is being created through the formulation of two components. Thus, asset twins give you the opportunity to let your study several interactions of those components. It creates a domain of performance that has the ability to be processed while turning into accurate insights.

- Unit or System Twins:

The next category of digital twins involves the next level of magnification of data. Unit or system twins consist of providing you to see how different assets work together in order to accurately create the whole functioning system. This type of digital twin provides the visibility affiliated with interactions of different assets. Moreover, it has the possibility of suggesting enhancements to accurate performances.

- Process Twins:

Process twins act as the vast format of magnification, also referring to the macro interpretation. It works in revealing how several systems work together in order to form an entire facility of production. It could be working in finding whether those systems are effective enough to generate compelling efficiency along with recognizing the possibility that any delayed systems will affect the others. It is the most versatile work of process twins to analyze the accurate schemes of timing which have the tendency to impactfully influence the entire effectiveness.

Read Here: User Interface of GA4: How Satisfied are you with its Features and Functionalities?

Read Here: Telegram’s Privacy Claims Put to the Test: A Review of the App in 2023

Advantages of Digital Twins

While going through all the elements of digital twin whether it is about its concept or categories. Now comes the query that consists of what is the value of a digital twin. So, let us look at all the benefits that are being provided through this effective solution.

- Greater Efficiency:

The most beneficial aspect of digital twin software is that it enables us with greater efficiency. This versatile solution helps in monitoring as well as mirroring the system of effective production, even in the situation of a new aspect being added to production. Involving thorough maintenance of high-level efficiency in the entire process of manufacturing.

- Compelling Research and Design:

The most highlighted utilization of digital twins is that they provide more compelling designs as well as research of products along with the data being solely analyzed regarding performance outcomes. This information assists in creating the insights that help the organizations to work for required product or service refinement prior to starting the process of the whole production.

- Final Processing Products:

There are several products that are at the end of their life cycle of production and require a final level of diverse processing. Thus, another efficient aspect that is being provided by the digital twins is that it assists the manufacturers to make an effective decision of what to do with the product at the final stage of production. Whether through recycling or taking other kinds of measures, digital twins help the producers to utilize those final products as well. In addition to that, through digital twins, they get to regulate which material of the product is précised to be collected.

Read Here: Top 10 Best Racing Games for Android and PC: The Ultimate Guide to High-Speed Fun

Read Here: Oppo Find N2 Flip Review: An Impressive Debut

Digital Twin Benefits to Generate Versatility of Projects

With the accurate use of digital twins solution, the users could attain the opportunity to sense and formulate the regular flow of data. This helps enhance the versatility of projects, as having the replica of physical objects assists in creating more impactful strategies for manufacturing.

The following categories of the project take utmost gains with the use of digital solutions:

- Projects that are Mechanically Complex:

Digital twins provide valid efficacy for complicated machinery as well as massive engines, consisting of immensely complex projects like automobiles, jet turbines as well as aircraft.

- Projects that are Physically Large:

Assistance for all the physically large-scale projects like bridges, buildings along with various compound structures which require the expertise of engineering.

- Projects of Manufacturing:

This helpful solution excels at facilitating the streamlined process, which you are likely to find in an industrial environment along with multiple machine systems and their functioning.

- Projects of Power Equipment:

Digital twins involve helping in mechanisms for various varieties of equipment, whether it is about transmitting or generating power.

Wrapping Up!

Therefore, it could be easily said that digital twins are effectively beneficial for all users. Whether it is about enabling better research and design of products or greater efficiency, it acts as a dynamic virtual copy of the physical asset, system, or even various processes. While discussing why digital twins are important, it could be easily determined that it is beneficial in correctly reflecting physical objects. From involving different types depending on various levels of product magnitude, to assisting in several categories of projects, digital twins solution is versatile in all the phases of production. Through its pristine interpretation, you can easily determine data about all physical objects from virtual perspectives.